Introduction

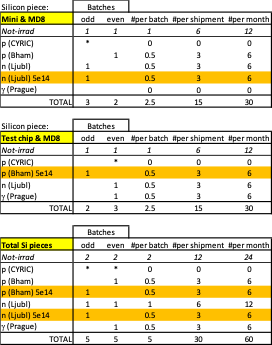

The quality assurance document specifies the measurement programme to be carried out on the different test devices sampled from wafers in the different batches to produce the different types of barrel and forward strip sensor being produced by Hamamatsu Photonics for ATLAS ITk. Devices are to be regularly irradiated with neutrons at the Ljubljana (JSI TRIGA reactor); protons at the Birmingham cyclotron (MC40 27MeV-37MeV); and photons at UJP Prague (60Co gamma irradiation). These will be complemented by less regular 70 MeV proton irradiations at CYRIC by Tsukuba. The proposed batch sampling is described in Table 1 from here.

All delivered devices must demonstrate the post-irradiation requirements up to a fluence of 1.6×1015 neq/cm2, and an ionizing dose of 660 kGy (66 Mrad) listed below. These figures assume an annealing period of 7 days at +25 °C (or 80 min. at +60 °C) after completion of the irradiation, and measured at -20 °C (refer to the Strip Sensor Technical Specifications for the pre-irradiation acceptance limits of all parameters):

- Maximum operating voltage: to remain within the pre-irradiation acceptance limits.

- Total Leakage Current: < 0.1 mA/cm2, normalized to -20 °C, up to 500V;

- Bias-resistor resistance, RBIAS (Polysilicon): to remain within the pre-irradiation acceptance limits

- Inter-strip resistance, Rint: to remain within the pre-irradiation acceptance limit when biased to 400V or above, at a temperature of -20 °C.

- Inter-strip capacitance, Cint: to remain within the pre-irradiation acceptance limits when biased to 400V or above, at a temperature of -20 °C.

- Micro-discharge onset voltage, VMD: >500V. In addition to the measurement of the onset voltage of micro-discharge, a measurement of electrical noise of strips as a function of bias voltage is another way to identify the onset of micro-discharge, by connecting the strips to readout electronics with an effective peaking time of 25 ns

- Collected charge: CCE > 6350 electrons per minimum ionizing particle (MIP) at 500V

For entry of the database it is required for each tested object to develop at least the following:

- Measurement output datafile formats

- Parameter extraction algorithms

- Test properties and parameters

- Database reporting.

We expect the measurement procedures to be extracted from here unless otherwise specified.

Key properties and parameters of the tests are to be stored in the database (DB) for each QA test, where a parameter is something that is measured, and a property is a "modifier" or "condition" of the measurement. The distinction between properties and parameters is important as thresholds can be established in the DB for parameters but not for properties. Derived parameters and extracted parameters will be calculated from the raw parameters by means of the parameter extraction algorithms. In general, only extracted parameters will be uploaded to the DB, however, in some special cases raw or derived parameters will also be uploaded for the purpose of comparison among devices. The text files containing raw data from the measurements will be uploaded as an attachment to the test. Thresholds are also defined for each test. Providing the device satisfies these conditions, a pass flag can be assigned for the test.

Since the DB does not have the capability to store units associated with parameters, all sites will need to use the same units. In general, SI units will be used, except for [cm], [µm], [minutes] and [pF].

The quality assurance document specifies the measurement programme to be carried out on the different test devices sampled from wafers in the different batches to produce the different types of barrel and forward strip sensor being produced by Hamamatsu Photonics for ATLAS ITk. Devices are to be regularly irradiated with neutrons at the Ljubljana (JSI TRIGA reactor); protons at the Birmingham cyclotron (MC40 27MeV-37MeV); and photons at UJP Prague (60Co gamma irradiation). These will be complemented by less regular 70 MeV proton irradiations at CYRIC by Tsukuba. The proposed batch sampling is described in Table 1 from here.

All delivered devices must demonstrate the post-irradiation requirements up to a fluence of 1.6×1015 neq/cm2, and an ionizing dose of 660 kGy (66 Mrad) listed below. These figures assume an annealing period of 7 days at +25 °C (or 80 min. at +60 °C) after completion of the irradiation, and measured at -20 °C (refer to the Strip Sensor Technical Specifications for the pre-irradiation acceptance limits of all parameters):

- Maximum operating voltage: to remain within the pre-irradiation acceptance limits.

- Total Leakage Current: < 0.1 mA/cm2, normalized to -20 °C, up to 500V;

- Bias-resistor resistance, RBIAS (Polysilicon): to remain within the pre-irradiation acceptance limits

- Inter-strip resistance, Rint: to remain within the pre-irradiation acceptance limit when biased to 400V or above, at a temperature of -20 °C

- Inter-strip capacitance, Cint: to remain within the pre-irradiation acceptance limits when biased to 400V or above, at a temperature of -20 °C

- Micro-discharge onset voltage, VMD:> 500V. In addition to the measurement of the onset voltage of micro-discharge, a measurement of electrical noise of strips as a function of bias voltage is another way to identify the onset of micro-discharge, by connecting the strips to readout electronics with an effective peaking time of 25 ns

- Collected charge: CCE > 6350 electrons per minimum ionizing particle (MIP) at 500V

For entry of the database it is required for each tested object to develop at least the following:

- Measurement output datafile formats

- Parameter extraction algorithms

- Test properties and parameters

- Database reporting.

We expect the measurement procedures to be extracted from here unless otherwise specified. Key properties and parameters of the tests are to be stored in the database (DB) for each QA test, where a parameter is something that is measured, and a property is a "modifier" or "condition" of the measurement. The distinction between properties and parameters is important as thresholds can be established in the DB for parameters but not for properties. Derived parameters and extracted parameters will be calculated from the raw parameters by means of the parameter extraction algorithms. In general, only extracted parameters will be uploaded to the DB, however, in some special cases raw or derived parameters will also be uploaded for the purpose of comparison among devices. The text files containing raw data from the measurements will be uploaded as an attachment to the test. Thresholds are also defined for each test. Providing the device satisfies these conditions, a pass flag can be assigned for the test.

Since the DB does not have the capability to store units associated with parameters, all sites will need to use the same units. In general, SI units will be used, except for [cm], [µm], [minutes] and [pF].

Table 1: Irradiations of the test pieces.

For each device (Mini&MD8 or TestChip&MD8) registered in the DB, the following component properties should be recorded:

- Label (string)

Following irradiation, the following test should be uploaded to the DB with the irradiation data:

- IRRADIATION: Irradiation of test pieces and sensors

The following test-specific properties should be recorded:

- Irradiation Site: (Required) Irradiation site where the samples were irradiated, e.g ‘Birmingham’ (string)

- Particle and Energy: (Required) Irradiation particle and energy [particle (energy)], e.g ‘Protons (23 GeV)’ (string)

- Nominal fluence: (Required) Nominal fluence of the irradiation (neq/cm2)(float)

- Nominal TID: (Required) Nominal ionising dose of the irradiation [Gy] [ (float)

- Hardness Factor: (Required) Assumed hardness factor for hadron irradiation (dimensionless) (float)

After irradiation, the following (float) parameters should be recorded

- Actual fluence: (Required) Actual fluence received by the samples during the irradiation (neq/cm2) (float)

- Error_on_fluence: (Required) [neq/cm2] Expected error on fluence (float)

- Actual TID: (Required) Actual total dose received by the samples during the irradiation (Gy) (float)

- Error_on_TID: (Required) [Gy] Expected error on TID (float)

- Annealing temperature: (Required) Temperature of annealing (°C) (integer)

- Annealing time: (Required) Time of annealing (min) (integer)